Ecology Unit: What is it?

An Ecology Unit, as name indicates, is a set of ltration process arranged systematically in a machine to get

rid of the unwanted impurities from the kitchen exhaust air. It’s an air puri cation Unit which removes oil,

grease/fatty material, smoke, and odor from kitchen exhaust air. is puri cation may be achieved using

mechanical ltration, electronic ltration and most of the time using combination of both. Mechanical

Filtration System consists of a series of mechanical lters arranged systematically whereas Electronic

Filtration Units consist of electrostatic precipitators (Collectors) along with mechanical lters for air

puri cation. An odor-removal-system using activated carbon/charcoal and an exhaust fan follows

mechanical/electronic ltration system.

Following are the modules/sections of a regular Ecology Unit:

Aluminum Pre‐Filter (G2 Grade – UL 900):

Metallic washable pre‐ lters with di erent thicknesses made of slitted and

expanded aluminum with hundreds of ba es made to arrest the oil, grease anddust. Owing to their excellent dirt holding capacity and ability to perform in high

moisture conditions, they are suitable for use as grease lters in kitchen hoods.

e average arrestance is 57‐81% and classi ed as G2 in accordance with

ASHRAE rating MERV 4. is lter is designed to remove high oil and grease

content from the exhaust air.

e metallic lter is washable type and requires

regular maintenance by washing the lter in a solution of detergent & warm

water and dried with compressed air.

Electrostatic Precipitator (ESP):

two stage Electrostatic Precipitator having a charging (ionizing) section as rst stage and collection section as second stage is included in the unit.

The charging section consists of ionizing wires of 0.010 inches diameter Tungsten to prevent corrosion and damage.

Wires are xed at one end and spring mounted on the other for ease of maintenance.

Collection plates are of minimum 0.025 inches thick aluminum.

The ESP includes a solid state, dual voltage and self‐regulating power supply

The power supply is housed in a hinged power door and is sealed from the airstream.

The ESP includes a 2″ thick pre aluminum mesh lters.

The ESP can either supplied in manual wash type or auto wash type as per the project

requirement. A drain-pan and drain connection can be provided in the cabinet if

required for removal of excess oil and grease owing down.

Bag Filters (F7/F8/F9 Class): (UL 900)

Single header pocket bag lters are made from high quality synthetic media. It

comprises of a unique matrix of primary and secondary synthetic bers with a

thin layer of high strength spun bond scrim on the air leaving side to increase

filter stability and prevent particle migration. is media design ensures a low

initial pressure drop, a high dust holding capacity and a long lter service life.

the filters are designed for a continuous operating temperature up to 93 0C.

the filters are classi ed F7/F8/F9 in accordance with EN779-2012 Standard and

can be supplied as per above classi cation or any other classi cation as

required.

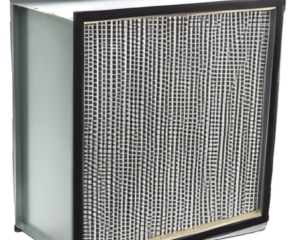

HEPA Filters (H13/H14 Class):

HEPA lters consisting of rigid pleated media pack with aluminum separator,

provide high e ciency air ltration on ne particles at the lowest possible

resistance.

the media pack is enclosed in a galvanized steel frame assembly.

the HEPA lter incorporated in our units is rated above 99% e ciency (99.997%) on

0.3 micrometer challenge aerosol with Class H13 European classi cation in

accordance with EN1822 Standard.

Cartridge Type Carbon Filter:

The carbon lter has a galvanized steel frame measuring di erent size according

to requirement with provision to t multiple cartridges lled with carbon media

to control odor.

The cartridges are made of galvanized steel with each cartridge

measuring 145mm in diameter and 450 mm in length. Each canister can hold up

to 2.8 kg of carbon media.

The quantity of cartridges depends upon the air

volume and the application intended.

V Bank Rigid Carbon Filters:

Carbon lters having pleated compact lter with activated carbon media as

standard. Other carbon media can be provided as per project requirement to control speci c odors.

control speci c odors.

The ese are high impact polystyrene cells having pleat packs

arranged in V shape to utilize maximum quantity of media for the given face

area.

the filters can be installed or removed by sliding in the tracks provided in

the cabinet. Each lter size is 24” x 24” x 12” thickness and contains 4.5 kg of

densely packed granular microstructure carbon ensuring higher e ective active

area per kg of media, resulting in high e ciency in odor removal.

Exhaust Fan:

The unit includes belt driven centrifugal backward curved Double Inlet Double

Width fans with AMCA certi cation.

The fan scroll is hot galvanized sheet steel.

The impellers are manufactured from high grade cold rolled steel with epoxy

coating.

The impellers are statically & dynamically balanced from factory. All

fans are tted with high quality ball bearings.

The motor is TEFC, class ‘F’ insula

tion and IP55 protection.

The motors are tted on adjustable motor base plate

for easy belt adjustment. Fan drives are rated at %150 of maximum motor

power.

The fan motor assembly is mounted on spring vibration isolators.

fan carries AMCA SEAL for certi ed air & sound performance ratings.

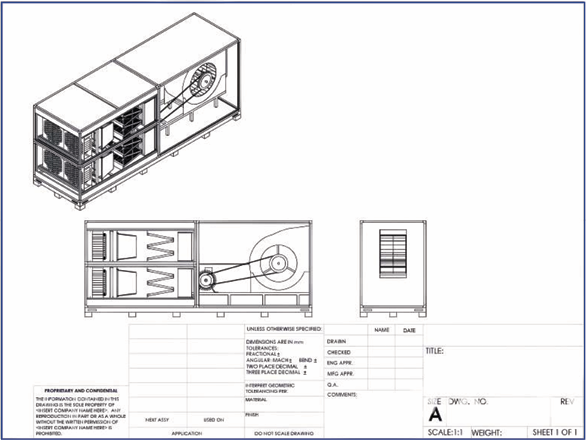

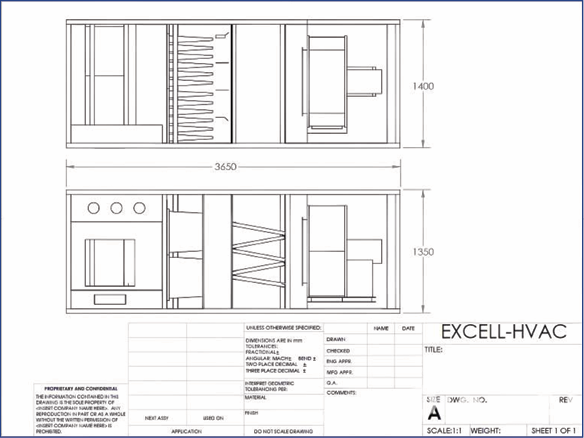

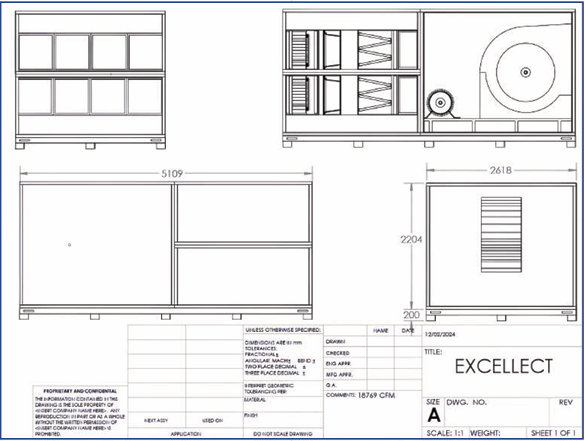

The Body:

All the above sections are enclosed in a double skin mild steel construction with the mechanical/electronic

filters, carbon lters and fan tted inside the cabinet.

The outer skin is 0.9mm MS, powder-coated and the inner

skin is of 0.7mm galvanized steel sheet.

The framework is made MS pro les, welded and powder-coated.

The standard sandwich panel is 25 mm thick lled with either rockwool, or berglass as insulation material.

The cabinet can also be manufactured with 50 mm thick panels if required.

The cabinet has removable type access

doors for cleaning, maintenance & replacement of filters.

same reinforcements across the unit base.

The entire cabinet is mounted on a MS C-channel with

The cabinet can also be supplied with a drain pan and drain

connection if required for removal of excess oil and grease owing down the ESP.

Filter Status Panel:

A Filter status panel can be provided to indicate the status of the individual mechanical lters using digital

di erential-manometers with pilot light & buzzer alarm indication for lter dirty signal in order to clean or

replace the respective lters.

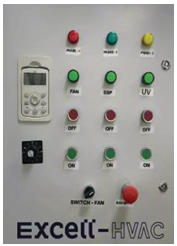

Fan Control Panel:

The unit can be supplied with an IP65 rated cabinet housing either STAR or

DELTA or digital VFD controls (for the ecology unit fan/motor).

The panel includes switch having variable speed selector for controlling the fan speed, Hands – Auto ‐ O and re alarm interfacing.

The panel includes switch having variable speed selector for controlling the fan speed, Hands – Auto ‐ O and re alarm interfacing.

The filter status indications canbe incorporated in this panel so as to have a single control panel for fan starter

and lter status.

The panel incorporating filter status will indicate the status of

the individual mechanical filters and pilot light & buzzer alarm indication for

filter dirty signal in order to clean or replace the respective filters.

The panel can also be supplied with provision to provide the status of the filters to the building

management system (BMS).