The PLASMA® Aluminum Jacketing is an attractive, maintenance-free aluminum jacket that satisfies most requirements for insulation protection with the advantage of low cost. The PLASMA®

Aluminum Jacketing is furnished from Aluminum Alloy 3003 with a temperature of H14.

The PLASMA® Aluminum Jacketing is suitable for most general purposes in industrial conditions and commercial buildings that use aluminum jacketing as the protection of insulation.

The PLASMA® Aluminum Jacketing insulation systems are commonly used in the commercial sector for chilled water applications, as well as transportation walls, floors, military shelters, clean rooms, roof tops, and ducting.

The PLASMA® Aluminum Jacketing provides excellent weather and mechanical protection on insulated piping, tanks, and equipment.

The PLASMA® Aluminum Jacketing is duly coated with a Polysurlyn Moisture Barrier (PSMR), which offers additional protection from galvanic and chemical corrosion

The Polysurlyn Moisture Barrier (PSMR) coat on the PLASMA® Aluminum Jacketing is an engineered three-layer coextruded film of polyethylene and Surlyn polymers with a total film thickness of 3 mils (76 µm) and is heat laminated in the factory to the interior surface of the aluminum jacketing. It is especially suited for service in which the moisture retarder might come into contact with excessive amounts of moisture for extended periods of time.

The Polysurlyn Moisture Barrier (PSMR) coat protects against galvanic corrosion caused by contact of dissimilar metal in the presence of moisture and chemical corrosion caused by installing sheets over damp insulation materials

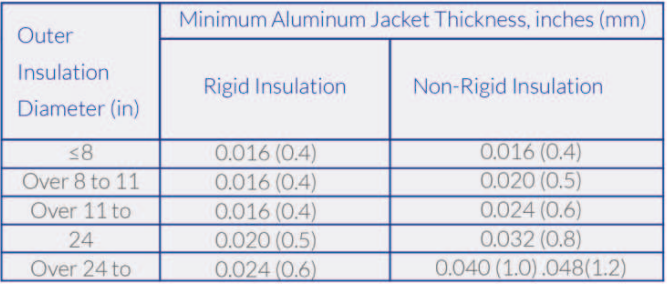

The most commonly specified gauges used for rolled jacketing are 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1mm, and 1.2mm.

The PLASMA® Aluminum Jacketing recommends the thickness of aluminum jacketing used based on the outer diameter of the insulation system per the requirements of ASTM C1729.

The recommended thickness is detailed below.

The PLASMA® Aluminum Jacketing is available in rolls (Smooth, Stucco, or 3/16″ Corrugation) and a variety of prefabricated systems which eliminate the necessity of field fabrication.

The primary function of a factory-applied integral moisture retarder is to retard galvanic or chemical corrosion at the metal-insulation interface. It should be applied only over dry inhibited insulation.

The PLASMA® Aluminum Jacketing offers a complete metal jacketing system to always provide excellent mechanical protection for insulated piping, vessels, and equipment