All mechanical equipment such as air handling units, ventilation fans, and blowers create noise and vibration transmitted through the duct system.

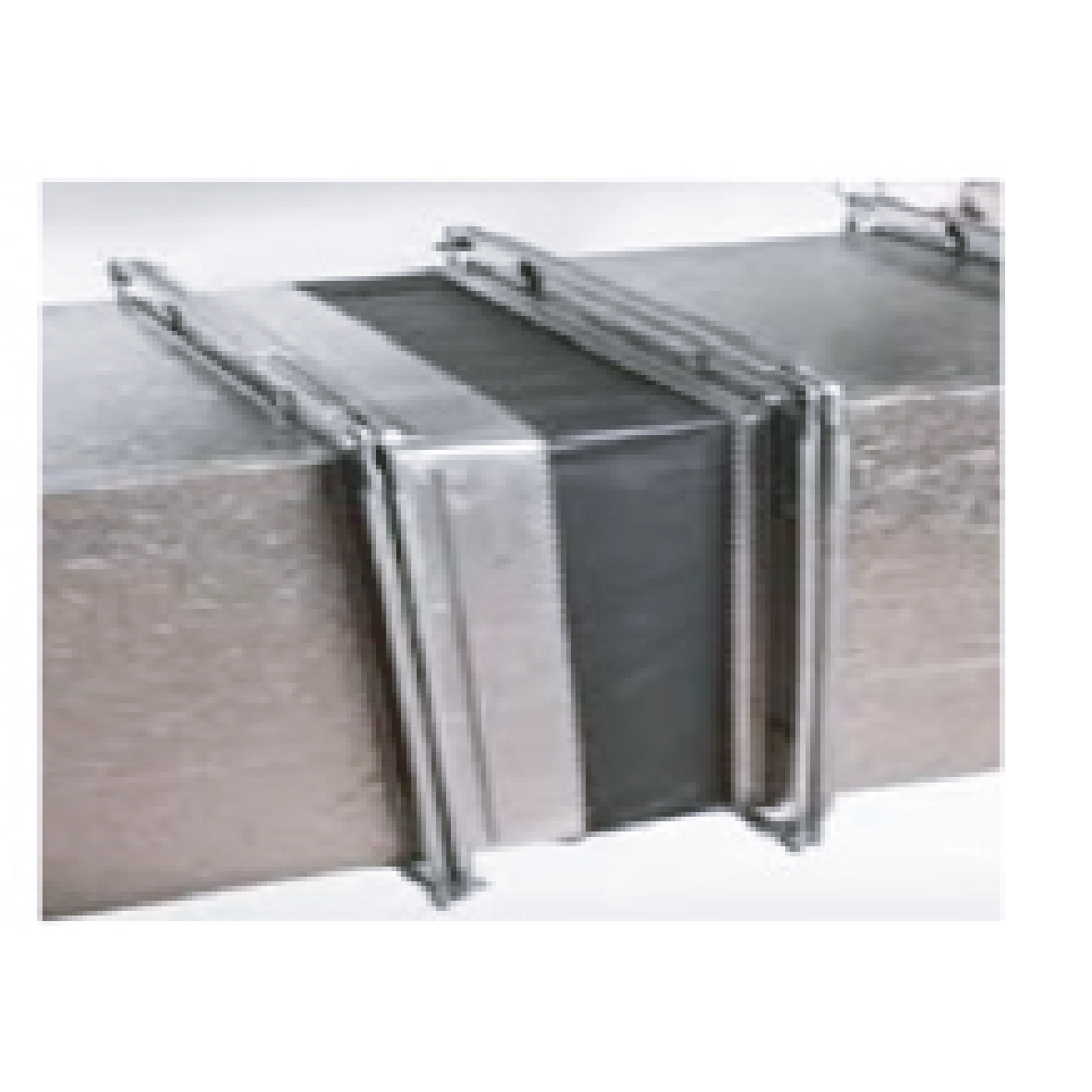

To isolate the vibration and noise, an air-tight flexible joint is formed by attaching a layer of fabric to two strips of metal on both sides. This flexible joint is called a “Flexible Duct Connector.”

The EXCELL Flexible Duct Connectors were specially developed with an advanced locking system for metal-to-fabric joints, ensuring extremely high mechanical strength and airtightness.

The EXCELL Flexible Duct Connectors offer different types of fabric, such as vinyl and neoprene, and are even suitable for any harshest operating environment with different metal widths and gauges to meet all commercial and industrial requirements.

The most critical part of a Flexible Duct Connector is the fabric, which should be selected to suit the typical requirements of each installation.

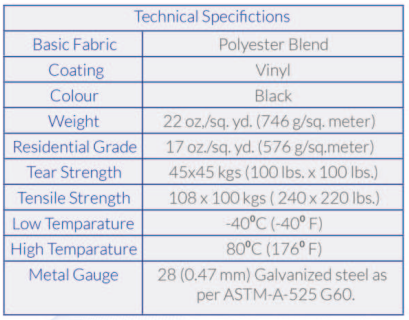

Vinyl is the most commonly used fabric for all air duct installations due to its high tear strength. Its technical specifications and features are detailed below

Features:

- – Excellent water resistance

- – Excellent all-purpose fabric

- – Excellent flexibility

- – Excellent resistance to oil, grease, and alkalis.

- – Unaffected by mildew

- – Airtight and waterproof

- – Class 1 as per ASTM-E84

- – Surface Burning Characteristics.

Note: All Specification Values shown in this catalog are typical and vary within accepted commercial tolerance.

The EXCELL Flexible Duct Connector is manufactured as per the standard quality policy of ISO 9001:2015